BS group Oxidized Bitumen 85/35 is suitable for sealing saw cuts and joints where there is expected to be the minimum amount of moving in the joint. BS group Blown bitumen grade R85/35 or Oxidized Bitumen 85/35 is produced by passing air through the penetration grades.

- +98-5632255131

- Sat - Fri: 8:00 - 16:00

- bsgroup.ir@gmail.com

Oxidized bitumen

Blown bitumen grade 115/15, 90/40, 150/5, 85/25, 90/15, 75/25, 95/25

Blown bitumen grades or Oxidized Bitumen are produced by passing air through the penetration grades in the controlled temperature. Oxidized bitumen characterized by being a product of great thermal amplitude. In fact, this special and controlled process gives the bitumen rubbery property more than its original formula and makes it simply harder bitumen.

Blown bitumen grades or Oxidized Bitumen are produced by passing air through the penetration grades in the controlled temperature. Oxidized bitumen characterized by being a product of great thermal amplitude. In fact, this special and controlled process gives the bitumen rubbery property more than its original formula and makes it simply harder bitumen.

Oxidized bitumen can be applied in any kind of work because it has flexibility to cold, has no sag at high temperatures and has good adhesion. they are typically used in roofing operation, pipe coating, under sealing for Portland cement concrete pavements, hydraulic application, sound dampening felts and under carriage sealant in the automotive industry, electric cable joint protection, joint filling compound, sealant compound, manufacture of paints and many others.

BS group oxidized bitumen is available in different grade as 115/15, 90/40, 85/25, 85/25, 90/15, 95/25, 75/25, 150/5, 105/30. We are also capable of producing other grades of Blown Bitumen upon request by our customers.

Oxidized Bitumen high softening temperatures qualify them as excellent sealant for prevention from bleeding in high temperature applications. Blown Grade Bitumen shall be broken up into small pieces (for blown grade in molded cake form) and heated slowly to the application temperature of 220ºC to 230ºC. Some of the major advantages of Oxidized Bitumen are that it is completely water resistant, highly flexible and durable. Further, it is chemically very stable.

Oxidized bitumen 85/40 is semi solid oxidised grade of pure petroleum bitumen categorized in polycyclic aromatic hydrocarbons is normally used for different purposes in the construction business.

BS group Oxidized Bitumen 90/10 is semi solid grade of pure petroleum bitumen manufactured by air-blowing through an asphalt flux. In fact, Oxidized asphalt 90/10 (in another word blown bitumen 90/10 or bitumen R90/10) is based on petroleum bitumen which is made by blowing grade 60/70 bitumen by hot air.

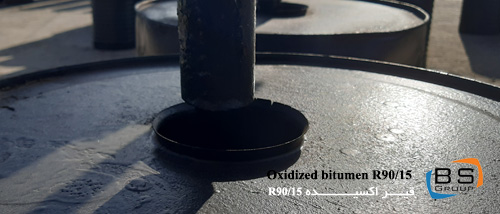

BS group Oxidized (Blown) Bitumen 90/15 is produced by either continuous or Staggered Blowing Process. Heated Penetration Grade bitumen under controlled environment is blown with air which controls the oil content in the bitumen while it oxidized.

BS group oxidized bitumen 90/40 is based on petroleum bitumen which is made by blowing asphalt 60/70 by very hot air. Blown bitumen 90/40 is manufactured from fine 60/70 bitumen in BS group refinery to meet EN and ASTM standard specifications and guarantee high quality products for our clients.

BS group Blown bitumen grade R85/25 or Oxidized Bitumen 85/25 is produced by passing air through the penetration grades. This process gives the bitumen more rubbery properties than its original formula and bitumen R85/25 are simply harder bitumen.

BS group oxidized bitumen 95/25 is a standard oxidised grade bitumen usually used for various purposes in construction business. R95/25 is normally used as a base raw material for bituminous pipe coating, roofing membranes, various water proofing purposes and coats in the automotive industry.

BS group Oxidized Bitumen 105/15 is the semi-solid oxidized grade of petroleum bitumen categorized in polycyclic aromatic hydrocarbons is normally used for different purposes in the construction industries.

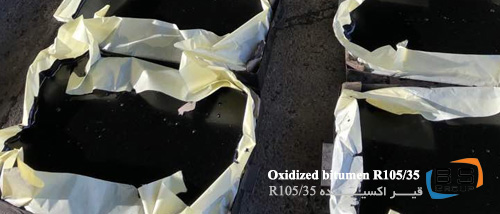

BS group Oxidized Bitumen 105/35 is semi solid grade of pure petroleum bitumen manufactured by air-blowing through an asphalt flux. In fact, Oxidized asphalt 105/35 (in another word blown bitumen 105/35 or bitumen R105/35) is based on petroleum bitumen which is made by blowing grade 60/70 bitumen by hot air.

BS group Oxidised Bitumen 115/15 is based on petroleum bitumen which is made by blowing bitumen 60/70 by hot air. The most oxidized bitumen usable grade is bitumen 115/15.